Safety Glass

Safety glass is a type of glass with enhanced features that make it less likely to break or less likely to cause any harm if broken. Ittihad offers a variety of safety glass products:

The tempering process involves heating the glass up to 690 Degrees Celsius before cooling it down rapidly. This process generates compression stresses on the surface of the glass leaving the glass in tension, these additional stresses created increase the strength of the glass by 4 – 5 times. Tempered glass is considered a safety for the following reasons:

- Tempered glass is four to five times stronger than annealed glass.

- Tempered glass has a higher thermal strength when compared to annealed glass.

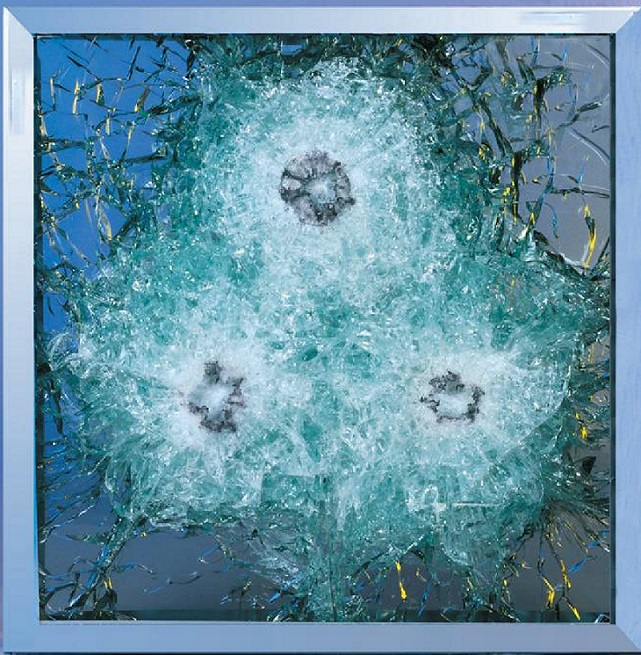

- Upon breakage, tempered glass will fracture into small harmless particles.

Annealed Glass Breakage Tempered Glass Breakage

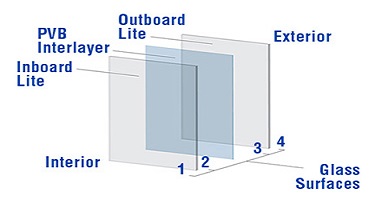

This process involves permanently bonding two or more pieces of glass with layers of polyvinyl butyral (PVB) interlayer, under heat and pressure, to create a single construction. The lamination process usually takes place in an isolated area where the humidity and temperature are strictly controlled. Lamination line operators are required to wear special clothing in order to maintain a clean, dust free environment. After washing the two pieces of glass, a PVB interlayer is placed between the two pieces before passing through a pressurized heating oven.

This process is required to remove any trapped air between the layers. The glass is then sent to an autoclave oven where it gets heated and subjected to extreme pressures that permanently adheres

the glass to the interlayer. Laminated glass is considered a class A safety glass. Certain types of bullet resistant, blast resistant, fire rated, and switchable panel (privacy glass) are manufactured using this process.

the glass to the interlayer. Laminated glass is considered a class A safety glass. Certain types of bullet resistant, blast resistant, fire rated, and switchable panel (privacy glass) are manufactured using this process.

Characteristics:

- Strength: The bond between the glass and interlayer strengthens the unit.

- Safety: Even if the glass breaks upon impact, the interlayer will resist penetration and the broken fragments will remain intact.

- UV elimination (Protects furniture from fading).

- Better Acoustical performance (Sound Insulation).

This product is usually constructed by joining several layers of glass with the layers of polyvinyl butyral (PVB) interlayer. Layers of polycarbonate are sometimes added to the construction. Ittihad Glass offers a range of bullet and blast resistant products. All products are tested and certified by accredited laboratories and organizations. Please contact our sales department for more information on this product.

Fire rated glass in its many forms is designed to provide protected areas for the containment of a fire within a building while simultaneously providing the aesthetic of transparency, visibility, and natural lighting. Specifying and choosing the correct type of fire-rated glass becomes more complex when considerations in addition to fire resistance become a factor. We are currently supplying different types of fire rated glass, all of our fire rated products are certified in accordance with international standards. Please contact our sales department to assist you in choosing the right product for your application.

During the production process of this type of glass, a steel wire mesh embedded into the semi molten glass before cooling. In the event of breakage, the wire will hold the broken pieces together preventing the glass from shattering. The impact resistance of the glass itself is similar to that of normal float glass, the purpose of the wire mesh it to prevent the glass from shattering when imposed to impact or high temperatures.